Model CS Capper

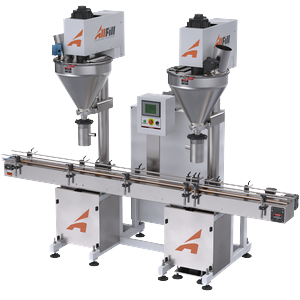

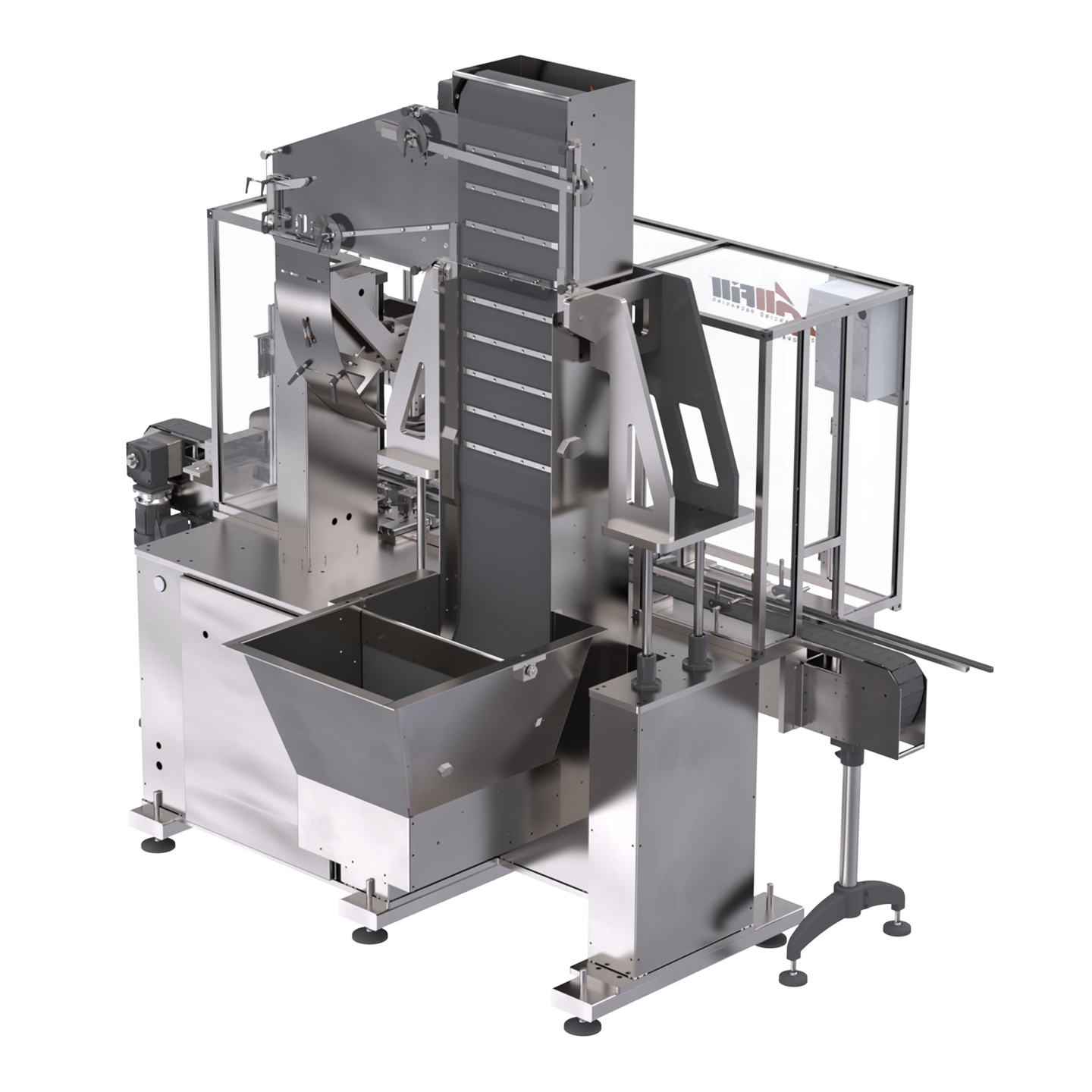

Capping Machines

All-Fill’s fully automatic two station inline chuck capper consists of stainless steel and anodized aluminum construction with an integrated 4.5 ft3 cap hopper and can be seamlessly integrated with ancillary packaging equipment. Standard 15" wide sorting cap elevator chain feeds and orients caps for placement. This machine includes a standard cap trap for one unique cap, or for both the first and second station chuck for one unique cap, which are designed per application. Controls offered include an integrated 7" color HMI touchscreen interface with operator controls and motorized height adjustment. A PLC package controlled with up to 50 pre-programmable recipes as well as 7 security levels.

Specifications

-

ControlsIntegrated 7" color HMI touchscreen interface with operator controls. PLC controlled with up to 50 pre-programmable recipes. 7 security levels (3 maintenance levels, 3 engineer levels, 1 administration level). Motorized height adjustment.

-

Electrical Requirements220 single phase. Transformer charge needed for any other voltages.

-

Pneumatic Requirements80 psi

-

RatesUp to 60-80 caps per minute depending on application.

-

ConveyorIncludes raised bed conveyor features hand wheel adjustment. The 11' conveyor is made of stainless steel and high-quality drive components. Features an electric motor and gear drive for low friction. 6” wide tabletop conveyor chain. Variable speed conveyor, adjustable guide rails will handle a wide range of container widths. The conveyor is supported by stainless steel and rounded legs for easy cleaning.

-

Cap Reject SystemIncludes a standard cap trap along with first and second station chucks for unique caps. The cap reject system will successfully identify a misapplied cap (high, low or no cap) and reject the container to a reject collection tray. Reject system consists of a Keyence high accuracy laser micrometer sensor and adjustable mounting bracket. A pneumatic pusher is the standard reject mechanism and other options are available based on application. Also features a cap foil detection/no foil reject.

-

Available OptionsAdditional Cap Trap. Additional Standard 1st Station Push Through Chuck. Additional Standard 2nd Station Torquing Chuck. Additional Bottle Clamps.

-

Induction Sealer IntegrationMounting and integration of customer preferred induction sealer.

-

Large Capacity Bulk Feed Elevator - OptionalUpgrade from the standard 15” wide sorting chain to an 18” wide sorting chain and increase the hopper capacity from 4.5 ft3 to 6.5 ft3 to allow for extra production prior to refilling.

-

Three Color Stack Light - OptionalThree color stack light: Red – Machine stopped/fault, Green – Machine running normal, Blue – Low caps.

All dimensions and specifications are subject to change without notice. Consult your sales representative or email us at info@allfill.com for exact information prior to purchase.

Common Applications

-

Soft Drinks

-

Squeeze Bottles

-

F-Style Bottles

-

Pharmaceutical Containers

-

Tapered Drink Containers

-

Spice Containers

-

Small Drink Containers

-

Round Bottles

-

Large Handle Bottles

-

Dish Soap Bottles

-

Square Bottles

-

Round Edge Bottles

-

Tall Bottles

-

Drink Containers

-

Pill Bottles

-

Large Drink Containers

-

Alcoholic Drinks

-

Nutraceutical Containers

-

Handled Containers

-

Jars

-

Energy Drinks

-

Carbonated Drinks

-

Drink & Juice Bottles

-

Drinks

-

Detergent Containers

-

Industrial Chemical Containers

-

Small Jars