Blog

CHECKWEIGHER DATA FEEDBACK

August 11th, 2022

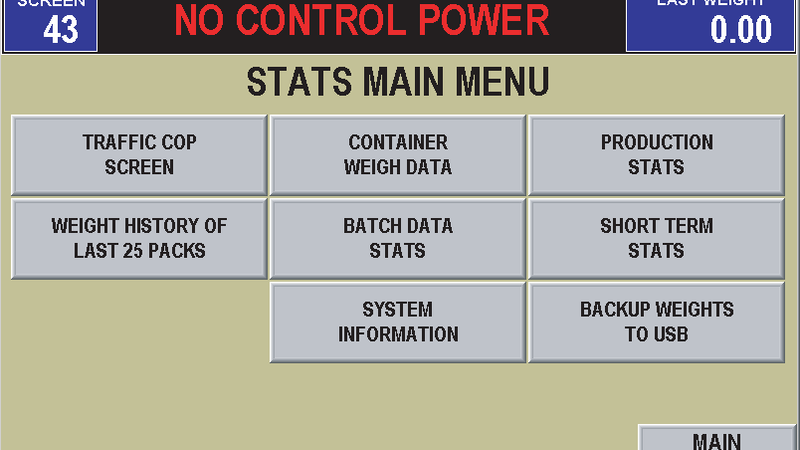

What is the Data Capture Software?

The software installs easily on most standard configuration PC’s (see “System Requirements”). Upon installation, a screen appears to specify connection to the All-Fill Checkweigher. Once connected, a central Weight Log screen appears listing the Setup Program’s Product Code, each checkweighed package, product code, time/date, and accept/over/under status. Print and save commands on this screen can specify where the weight data is recorded or listed in a printer. The save command allows data to be recorded as either ASCII text or comma delimited formats for use with other applications (i.e..,spreadsheets, databases, etc.) A current batch report screen lists relevant weight data for the current and most recent batch. A pie chart graph on this screen provides a graphic depiction of batch weights and status. A weight graph screen displays weight trending data over time with user-selectable maximum and minimum weight limits. An alarm log screen provides a summary of any checkweigher errors by type, date, and time. The weight graph and alarm log are for display/printing purposes only. Data is not written to any files

CHECKWEIGHER DATA CAPTURE SOFTWARE

Routes Checkweigher Weight Data Directly to Your Desktop Computer

The All-Fill Checkweigher data capture software is a PC-based utility to instantly transfer each container’s weight directly to a PC. Any All-Fill Checkweigher – CW-10, EW-8, PW-12, MW-16, HP-14, HW-15 equipped with CW700 controls can be used for data capture to your PC. The Data Capture Software can connect via an ethernet connection or RS-232 connection. Older All-Fill and Alpha Checkweigher models may require a software update to use the Data Capture Software. The software installs easily on most standard configuration PC’s (see “System Requirements”).

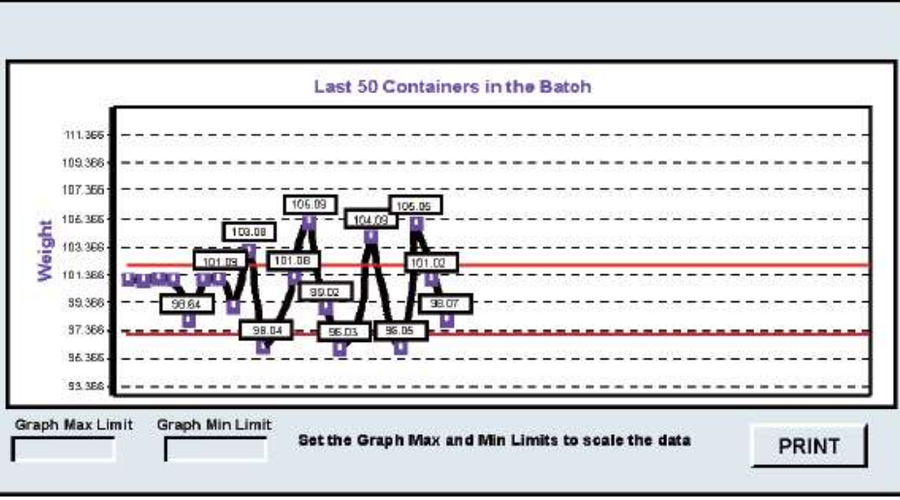

Upon installation, a screen appears to specify connection to the All-Fill Checkweigher. Once connected, a central Weight Log screen appears listing the Setup Program’s Product Code, each checkweighed package, product code, time/date, and accept/over/under status. Print and save commands on this screen can specify where the weight data is recorded or listed in a printer. The save command allows data to be recorded as either ASCII text or comma delimited formats for use with other applications (i.e.., spreadsheets, databases, etc.) A current batch report screen lists relevant weight data for the current and most recent batch. A pie chart graph on this screen provides a graphic depiction of batch weights and status. A weight graph screen displays weight trending data over time with user-selectable maximum and minimum weight limits. An alarm log screen provides a summary of any checkweigher errors by type, date, and time. The weight graph and alarm log are for display/printing purposes only. Data is not written to any files.

ADDITONAL SOFTWARE FEATURES

System Requirements:

The Single Weight Data Capture software has been designed for use with any PC running the Windows platform, version PC up to Windows 7. MS Office highly recommended for use of single weight data.

CHECKWEIGHER DATA OUTPUT TO USB

Routes Checkweigher Weight Data Directly to a USB drive

Weight and package data detected by any All-Fill Checkweigher can be recorded and stored for later or remote use with this software option. All relevant package data is recorded, including:

-

DATE/TIME

-

WEIGHING TIME

-

SETUP RECIPE NUMBER

-

PRODUCT NAME

-

TARGET WEIGHT

-

LAST WEIGHT

-

HIGH/LOW ACCEPTANCE STATUS

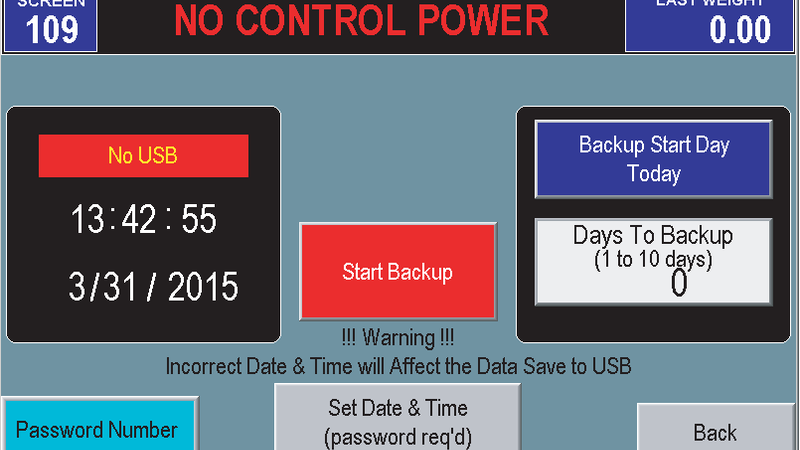

Data is sent to a Universal Serial Bus (USB) connector on the control enclosure. Data is provided in the industry standard Comma Separated Values (.csv) format for use with common spreadsheets and database applications. Any device equipped with a standard USB male connector can be connected to the Alpha Checkweigher. The software is installedduring assembly of the checkweigher and no special installation or configuration is required.

ADDITONAL SOFTWARE FEATURES

-

SET DATE AND TIME

Selection specifies calendar date and time for data recording.

-

START DAY

Selects when data will start to be collected. Starting days can be selected for the present or up to 7 previous days.

-

DAYS TO BACKUP

Selects length of data collection - From 1 to 10 day’s data can be specified.

-

START BACKUP

Collects data - A confirmation message briefly appears on the screen that data collection performed.